- ·Radial riveting machine

- ·Orbital riveting machine

- ·CNC riveting machine

- ·Riveting machine production line

- ·Self-piercing riveting machine

- ·Riveting machine assembly line

- ·Traffic sign riveting machine

- ·Rolling pressing riveting machine

- ·Rolling riveting machine

- ·Multi-function riveting machine

- ·Riveting press

- ·Rivetless riveting machine

- ·Pneumatic boosting riveting machine

- ·Truck frame riveting machine

- ·Multi-head riveting machine

- ·Double head riveting machine

- ·Horizontal riveting machine

- ·Automatic feeding riveting machine

- ·Screw nut automatic feeding riveting machine

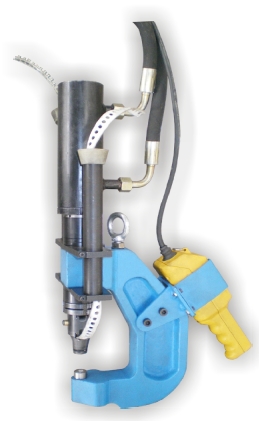

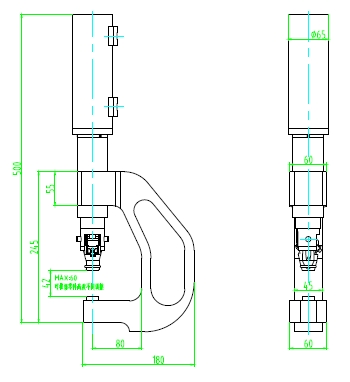

- ·Rivet hand gun

- ·Hand riveting clamp

- ·ladder making machine

We have research and study the self-piercing technology from the year of 1995 and the main purpose of for joint different metal material with good sealing and protect penetraition function. The main advantages are low energy consumption, use of small venues and pollution-free etc. Applicable scopes: coated steel sheet, aluminium, zinc, reinforced plastic, compound material etc.

Principle of Self-pircing

The end of rivet open a horn shape under the action of convave die and riveting pin at base layer to locking it with top layer. Generally the thicker layer at base and same thickness have no limited, ductile material at base layer. Metal material at base layer if joint metal with non-metal material.

Application of Self-piercing machine

■Automotive metal sheet components

■Washing machine, air-conditioning’s metal sheet etc

■Computer chassis, home appliances metal sheet etc

■Fan casing and industrial equipment application

■Busway’s industrial engineering applications

■Elevator’s metal sheet and other commercial facilities

■Other metal sheet connect occasio

Advantages of Self-piercing riveting machine

■Special purpose rivet with special rivet carry belt

■No need to drilling holes, no waste and no iron crap occurred

■Self-piercing processing allowed Non-metallic sandwich material

■No thermal stress concentration and no damage to the surface coating

■High dynamic strength and far superior to the traditional spot welding

■The self-piercing forming by special die with stamping and processed quality is stable

■By check the riveting point geometry size can judging the riveting quality

■No damage to plating or coating and no need after painting or plating