- ·Radial riveting machine

- ·Orbital riveting machine

- ·CNC riveting machine

- ·Riveting machine production line

- ·Self-piercing riveting machine

- ·Riveting machine assembly line

- ·Traffic sign riveting machine

- ·Rolling pressing riveting machine

- ·Rolling riveting machine

- ·Multi-function riveting machine

- ·Riveting press

- ·Rivetless riveting machine

- ·Pneumatic boosting riveting machine

- ·Truck frame riveting machine

- ·Multi-head riveting machine

- ·Double head riveting machine

- ·Horizontal riveting machine

- ·Automatic feeding riveting machine

- ·Screw nut automatic feeding riveting machine

- ·Rivet hand gun

- ·Hand riveting clamp

- ·ladder making machine

Vertical design // Orbital structure with hydraulic driving // Working bench is adjustable //

Max. riveting diameter Ф 12 mm (solid steel rivet)

Characteristics:

BM12 machine is a medium-sized radial hydraulic riveting machine, besides the utilization of the fifth generation technology, the machine is also equipped with screw lift table (Stationary Base part), the table has a trapezoidal groove clamps for the riveting die. The center of the working station is aligned with the spindle bore axis and it's used to better positioning the fixture. The riveting speed can be easily controlled with the installation of one-way valve oil. The digital electronic control time relay and digital counters has been installed to ease the user control. Oil tank can be combined or disassembled with the machine for easy transportation and assembly. Riveting speed can be easily controlled by Fluid path-way valve. The workbench is equipped with long stroke screw lift system and made convenience for the adjustment of the machine. As a result of the above function and radial design, the riveting operation goes with ease and the workpiece finishing is created smoothly.

Scope of application: The instrument appearance, daily hardware, electrical equipment ,

medical equipment and automobile parts etc.

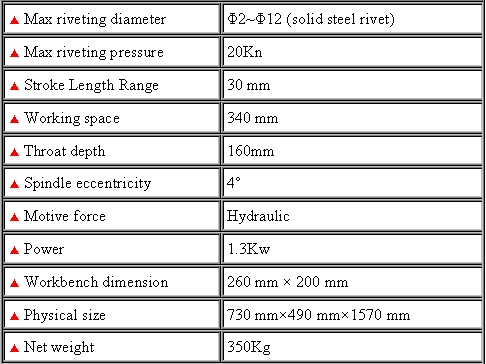

Technical Parameters: