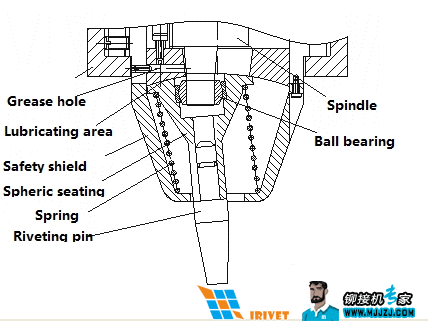

Radial Riveting Machine Spherical Joint Maintenance Guide

1. Lubrication: Spherical joint mainly uses lithium soap for lubricating process. Refill frequency is every 100 hours. If the joint constantly lack of lubricant, the friction will increase along with the temperature, leading to the acceleration of the worn.

2. Rivet head worn check: The length of rivet protruding head is extremely critical. The periodic check usually performed after every machine operation. If the deviation is more than 0.2mm tolerance in size, the center point will change over time and leading to bad rivet finishing also causes the damage of spherical joint inside.

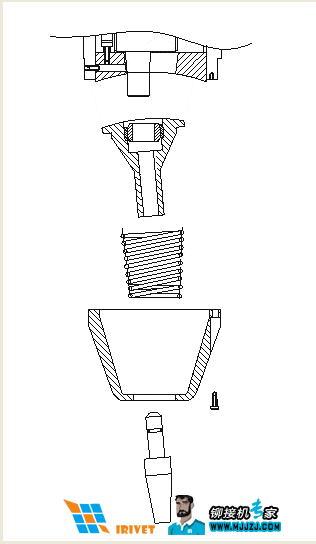

3. Instruction and note on Assembling and Dissembling:

① Rivet head:

Rivet head is relatively easy to install and uninstall. When uninstalling, gently hold and twisting the head with your hand and pull it downward.

Note: Never hammer the rivet head and it will cause damage to the joint!

② Spherical Joint:

Please following the steps to uninstall the joint if joint broken or joint worn:

a. Unscrew the black micro adjustment wheel cover.

b. Carefully unscrew 3 of the hex screw on the red safety cover and gentle remove the cover.

c. Gently pull down the riveting block (including the joint set)

d. Turn on the oil pump and press the foot switch. Turn off the oil pump when the piston has reached its lowest position.

e. Unscrew the screws with the screwdriver under the pistons. (Screws are for locking joint in position.)

f. Carefully pull down the spherical joint.

For installation, please refer the instruction backward, from " f " to "a".